Santa Clara, CA, USA – Silicon Valley startup, Arevo, has recently announced the creation of a 3D-printed carbon fiber commuter bike. The company is using the bicycle to demonstrate its design software and 3D printing technology, which it hopes can be used by bicycle manufacturers and in other industries where designers prize the strength and lightness carbon fiber parts but are put off by the high-cost and labor-intensive process of making them. The bicycle design is being hailed by the company as “the first truly 3D-printed bicycle.”

Arevo is known for its six-axis robotic 3D printing platform for manufacturing composite parts. The company raised $12.5 in series B funding. Avero is headed up by new CEO, Jim Miller, who previously worked at Amazon as Vice President of Supply Chain, and Google where he led the team that built the company’s main infrastructure, including the search engine, YouTube, Gmail, advertising and cloud businesses.

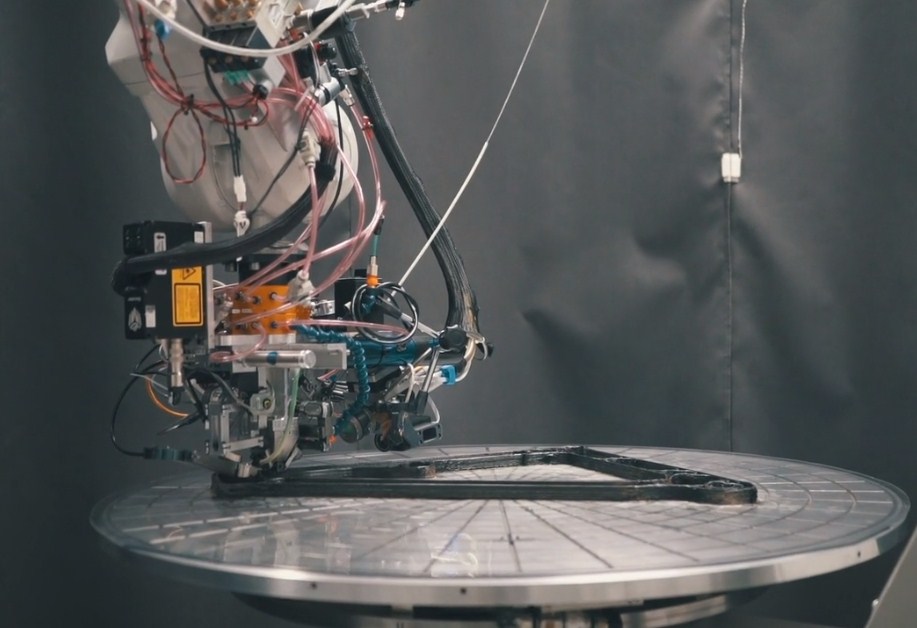

Arevo’s technology uses a “deposition head” mounted on a robotic arm to print out the three-dimensional shape of the bicycle frame. The head lays down strands of carbon fiber and melts a thermoplastic material to bind the strands, all in one step. Avero's process involves almost no human labor as the need for many man-hours of laying-up carbon. This allows Arevo to build bicycle frames for $300 in costs, even in pricey Silicon Valley.

“We’re right in line with what it costs to build a bicycle frame in Asia,” Miller said. “Because the labor costs are so much lower, we can re-shore the manufacturing of composites.” Arevo is in talks with several bike manufacturers, the company eventually hopes to supply aerospace parts. Arevo’s printing head could run along rails to print larger parts and would avoid the need to build huge ovens to bake them in.