Speaking to Selle Italia at Taichung Bike Week gave us an insight into their production and sustainability strategy, performance, and even a close-up look at a new green OE-targeted saddle.

Being in Taichung, Taiwan, Global OEM Sales Manager Alberto Curtolo was asked about where Selle Italia does their manufacturing. Considering a lot of the global leading manufacturers have many setups in Taiwan, Selle Italia proudly has a different arrangement. He said, “We ship to Taiwan, but all of our products are made in Italy and Romania. Of course, Taiwan is a good market for us; we ship a lot here, and many manufacturers make products in Taiwan, but we make everything in Europe.”

We can’t avoid talking about overstocking in environments like Taichung Bike Week, where many of the affected are present. Mr.Curtolo spoke frankly, but positively, about the situation and the outlook.

He said, “Overstocking has been a challenge, and the bike industry is dealing with it every day. From my perspective, we need to be positive in a positive way because, in just a matter of time, the number of customers and riders is higher than it was two years ago, which means the business can resume as usual.

“The problem is that during the pandemic, we got a “fake demand" from the market because the final consumer was looking for a bike and ordering the same bike five times in different shops, which created the “fake demand”.

“But, finally, the lead times have shrunk, and everything is returning to normal. The final consumers are still working and running, unlike two years ago, but we are also closed in the winter, especially in Europe, and the bike industry as a whole relaxes a little. It is normal for it to start again in the spring. We need to push to clean the stock, and we can restart in the normal way.”

“Normally, we discuss growth, but today we discuss business stability.”

Sales performance is inextricably linked to the market, and Mr. Curtolo shared his thoughts on the subject, saying, "As the market slows, it is difficult to think about performance. Normally, we discuss growth, but today we discuss business stability. The big challenge is to maintain the balance over the next year, but I am still optimistic. I believe the situation will improve between the end of 2023 and the middle of 2024.”

A Green New Saddle

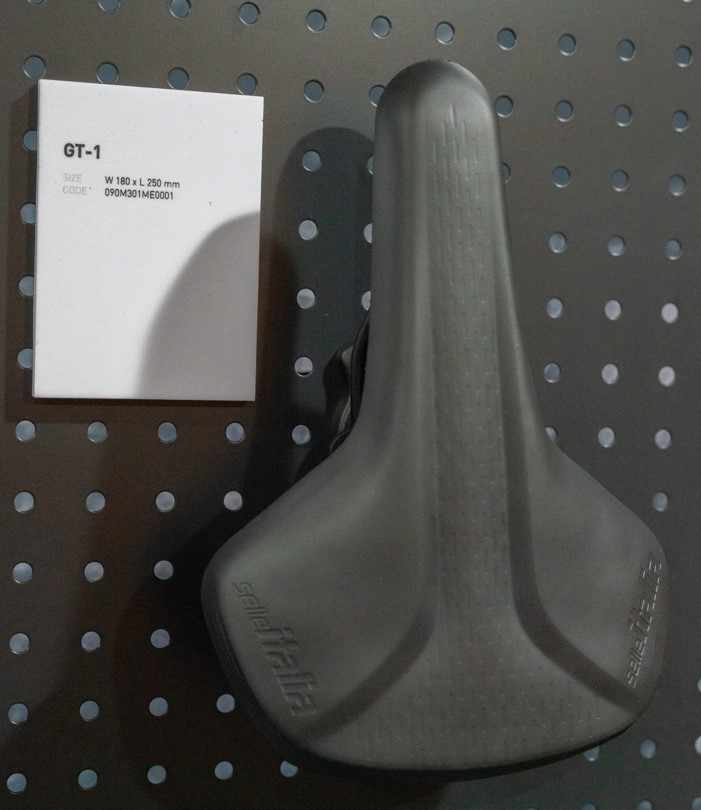

Selle Italia was hard at work at Taichung Bike Week, collaborating with OE customers on their latest GT-1 saddle (W180 x 250 mm) for commuting and e-bikes. Their latest saddle offers excellent sustainability and production efficiency while maintaining their renowned comfort and style.

“The GT-1 represents an entirely new approach to saddle design. It is an evolution.”

The top and bottom views of the GT-1.

The GT-1 dimensions are W180mm x L250mm.

Mr. Curtolo said, “The GT-1 represents an entirely new approach to saddle design. It is an evolution. We do not use glue to connect the shell to the padding, and the cover provides protection. The padding is injected, and we use an EVA foam that expands during the injection, contracts when it gets colder, and then connects with the shell.

“It means we can make a saddle without using glue, and it is easier to recycle because the padding is easier to separate from the shell, and it is a more environmentally friendly way to use the saddle.”

The GT-1 will first be seen for OEM, but they will release a nearly identical saddle with different features for the aftermarket, most likely at Eurobike next year.

Mr. Curtolo said, “We hope to find new customers who believe in and use this technology on their bikes. And we are confident in that because this saddle is an OE saddle for commuting.”

Aiding sustainability whilst boosting production

Selle Italia has become more efficient while also becoming greener. “It is not just the process's evolution; it is also a little bit of sustainability,” Mr.Curtolo said. “We began the sustainability project at Selle Italia three to four years ago. Another advancement is “Greentech” technology. Because the saddle is made entirely from a press injection mold, we connect the shell padding and cover using a knitting process because we use the same base material.”

“We can guarantee that using a Greentech saddle will save more than 50% of CO2 emissions.”

“That is a more sustainable product because we can guarantee that using a Greentech saddle will save more than 50% of CO2 emissions when compared to traditional saddles. Everything is made in Italy in a single location. Quality control is active throughout the machine, but the capacity is vastly different because, while one person can cover 30 saddles in a day using handmade cover technology, one person can make 6000 saddles using green technology. It is a new revolution, a new concept.” He added, “Glue is a nightmare from an ecological standpoint.”

From Selle Italia themselves, “Greentech is an optimized production technology that creates sustainability and 100% recyclable products without the use of polluting elements in a waste-free system. The Made in Italy process uses local manufacturers to further reduce CO2 emissions.”